Achieving accuracy and reducing waste are central to modern production goals. But how can industries ensure efficiency while maintaining high standards? What role does advanced technology play in refining processes? An advanced system has emerged as a cornerstone of modern manufacturing, effectively addressing these challenges.

Linear motion drives precision and eliminates waste in modern production by enabling consistent, controlled, and repeatable movements. This technology empowers industries to meet demand with reduced resource consumption and enhanced productivity, from assembly lines to automated systems.

Role of Precision Motion Systems in High-Quality Manufacturing

Precision is the foundation of high-quality manufacturing. Motion systems provide unparalleled accuracy through their ability to maintain consistent positioning and movement. These systems have actuators, guide rails, and sensors, which work together to ensure flawless operation. In electronics, where tolerances are incredibly tight, these systems ensure components are aligned and assembled accurately. For example, semiconductor manufacturing relies on the precise placement of microscopic parts, where even the slightest misalignment can result in product failure.

Minimizing Resource Waste Through Better Efficiency

Unnecessary waste often stems from inefficient processes or lack of control over materials. Controlled motion tools combat these inefficiencies by enabling precise control over movement, speed, and force.

- Material Utilization: Controlled motion tools reduce material wastage by ensuring that cuts, movements, and positioning are executed precisely. For example, in sheet metal processing, accurate positioning ensures optimal cuts, minimizing scrap material.

- Energy Efficiency: Advanced controlled motion tools are designed to consume less energy by reducing friction and unnecessary movement.

- Error Prevention: Improved control mechanisms minimize operational errors, reducing the need for rework or discarding defective products.

Boosting Output Without Compromising Quality

Production lines often face the challenge of maintaining speed without compromising quality. These systems excel in high-speed applications, ensuring smooth, stable operation even under demanding conditions. For instance, in packaging industries, materials must move quickly along the line while maintaining alignment and avoiding damage.

Linear motion technology ensures stability and synchronization, allowing systems to handle high-speed operations with minimal errors. Additionally, industries like automotive manufacturing benefit from this technology. It enables the rapid and precise assembly of multiple components.

Supporting Complex Automation Systems

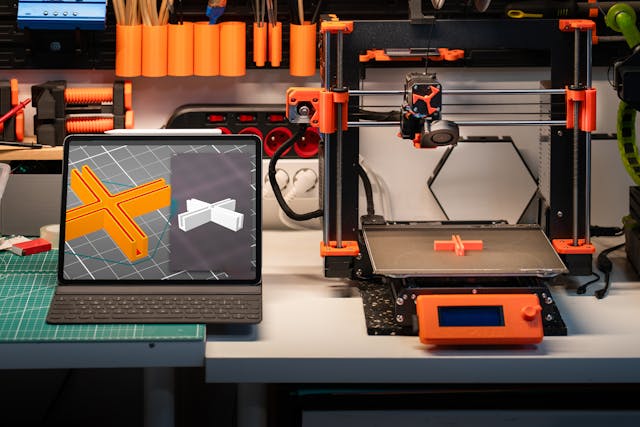

Automation is revolutionizing manufacturing processes, driving the need for advanced technologies capable of handling complex tasks. These technologies are essential to this shift, providing the precision and flexibility required for intricate operations.

- Integration with Robotics: These systems integrate effortlessly with robotic systems, enabling tasks such as multi-axis movement and synchronized actions. This is particularly useful in assembly lines where precise positioning and timing are crucial.

- Customizable Solutions: These systems can be tailored to meet specific application requirements, such as varying load capacities, travel lengths, or speed adjustments. This flexibility supports executing highly specialized tasks, such as surgical tool production or aerospace component assembly.

- Enhanced Monitoring: These systems often feature advanced monitoring capabilities, allowing operators to track performance in real-time. This ensures consistent operation and helps identify potential issues before they escalate.

Reducing Long-Term Costs Through Durability

A significant advantage of motion systems is their durability and long lifespan. Manufacturers can minimize long-term operational costs and avoid frequent replacements by investing in high-quality systems. These precision-driven mechanisms are designed to endure demanding conditions.

Materials like stainless steel and coatings that resist wear and corrosion ensure longevity. Additionally, many systems feature self-lubricating or low-friction components, reducing maintenance requirements and enhancing efficiency. These features provide a reliable solution that ensures uninterrupted production for industries operating in harsh environments, such as chemical processing or heavy manufacturing.

Enhancing Sustainability in Modern Production

Motiontechnologies contribute significantly to these efforts through energy efficiency, precise resource utilization, and improved process control. Energy-efficient designs inherent in these systems lower power consumption, helping industries reduce their carbon footprint without compromising productivity. Moreover, this technology enhances material optimization and waste reduction. As a result, these systems directly support resource conservation while improving overall production efficiency.

Also Read: How to Choose the Right Electric Actuators for Your Industrial Needs?

Selecting Advanced Motion Technology for Precision Applications

Selecting the ideal advanced motion solutions technology is essential for achieving accuracy and efficiency in demanding applications. High-precision systems require advanced solutions tailored to specific needs, including load requirements, motion type, and environmental conditions. Expert guidance is critical in navigating the complexities of motion technology.

From evaluating torque and load capacities to understanding the integration of motion controls, professionals in the field provide valuable insights that simplify decision-making. Tools like selection guides, technical resources, and engineering expertise can help businesses identify solutions that align with their goals. Leveraging the right resources and services ensures long-term success, whether addressing industrial automation or custom design requirements.

Linear motion systems are revolutionizing modern production by driving precision, efficiency, and sustainability. Their ability to enhance accuracy, reduce waste, and support advanced automation makes them an essential technology for industries striving for excellence. Adopting solutions that optimize performance while minimizing environmental impact will be key to staying competitive as manufacturing evolves.