The process of selecting the right actuator for industrial applications can feel overwhelming. What are the most critical factors to consider? How can you ensure that your choice meets operational demands while staying cost-effective? Answering these questions requires a clear understanding of your requirements and the features of available options.

Electric actuators have become crucial automation components because of their precision and reliability. Selecting the proper electric actuator for your industrial needs involves analyzing the environment, operational requirements, and system compatibility. This guide will walk you through the crucial considerations for making an informed decision.

Analyze the Operating Environment

The environment where the actuator will function is pivotal in determining its durability and efficiency. Temperature, humidity and exposure to dust or chemicals can directly impact performance. In high-temperature settings, choose actuators made with heat-resistant materials. For outdoor applications, weatherproof designs are necessary to prevent wear and tear. Moist or corrosive environments require actuators with enhanced sealing to avoid premature failure.

Calculate Load and Torque Requirements

Your application’s load and force requirements are essential factors in determining actuator suitability. Undersized actuators may fail under stress, while oversized ones lead to unnecessary energy consumption. These calculations ensure the actuator can handle its tasks without overloading, reducing the likelihood of mechanical strain:

- Identify the load’s weight, size, and movement type (linear or rotational).

- Calculate the torque or force needed to move the load effectively.

- Factor in external resistances such as friction, incline, or inertia.

Choose the Appropriate Motion Type

Understanding the motion type required for your application simplifies the selection process. Electric actuators are generally divided into two categories: linear and rotary. Linear actuators perform straight-line movement tasks like pushing, pulling, or lifting. They are ideal for conveyor systems, automated gates, and positioning platforms.

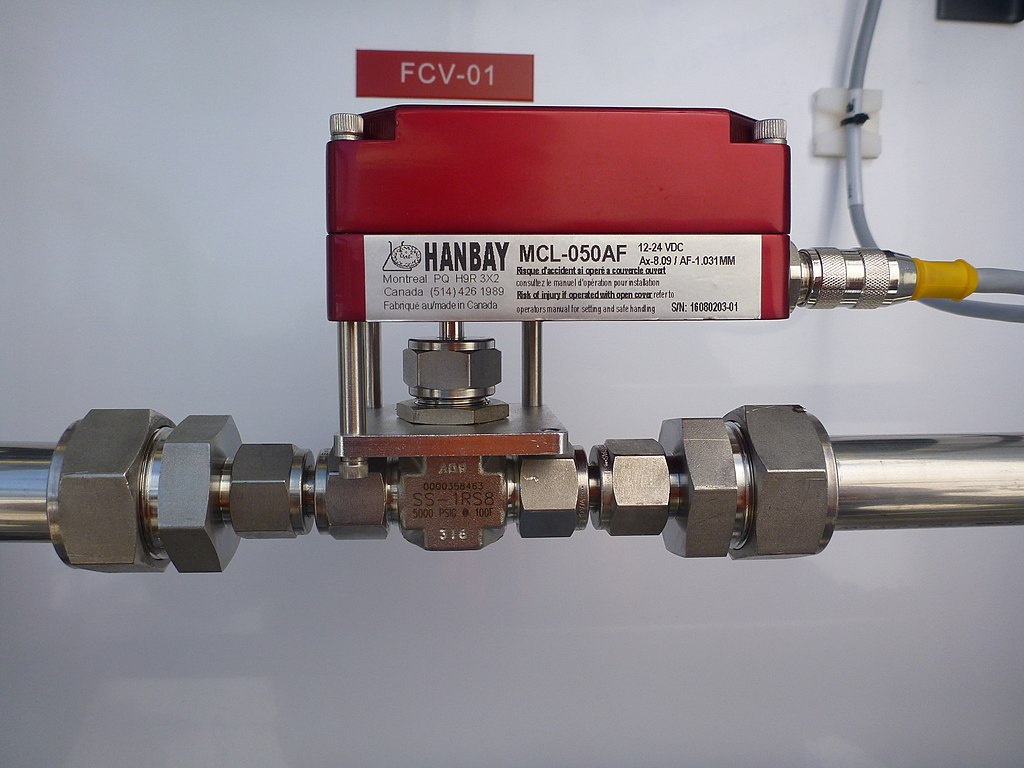

Rotary actuators, on the other hand, specialize in rotational movements. These are frequently used in applications such as valve operations and robotic arms. Matching the motion type to your specific task guarantees better performance and efficiency.

Evaluate Power Supply Requirements

Ensuring compatibility with the available power supply is an often overlooked but vital step. Mismatched voltage or phase requirements can lead to equipment malfunctions or energy inefficiency. Check whether the actuator operates on AC or DC power and ensure it aligns with your infrastructure. Additionally, prioritize energy-efficient models to reduce operational costs over time. For applications in remote locations, consider battery-operated options for flexibility.

Prioritize Control Systems and Feedback Mechanisms

Accurate control is a cornerstone of efficient operations, particularly in industries requiring precision. Modern actuators are equipped with advanced features to enhance functionality. Here’s how advanced control systems reduce human error and improve overall productivity:

- Opt for actuators with integrated sensors for position and speed feedback.

- Programmable control systems can adapt to varying requirements, improving efficiency.

- Ensure compatibility with existing automation systems for seamless operation.

Focus on Maintenance and Longevity

Reliable and durable actuators save time and costs by reducing the frequency of repairs and replacements. When evaluating options, prioritize ease of maintenance and durability. Actuators with self-lubricating components or modular designs simplify upkeep. Models made with wear-resistant materials last longer, even in demanding conditions. Additionally, select suppliers that offer warranties and readily available replacement parts to minimize downtime.

Ensure Compliance with Safety Standards

Safety is a critical factor in any industrial setting. Using actuators that meet safety and regulatory standards protects both employees and equipment. Look for overload protection, emergency stops, and fail-safe mechanisms. Verify certifications such as ISO or CE compliance to ensure adherence to industry standards.

Also Read: Engineered for Efficiency: Power Supplies to Match Your Vision

Consult Expert Support and Resources

Working with knowledgeable suppliers or manufacturers can simplify the decision-making process. Reliable vendor support offers guidance on product selection, installation, and maintenance.

Key Considerations When Choosing a Supplier

Working with a reputable supplier involves more than just purchasing the product. Look for partners who offer:

- Proven Track Record: Choose vendors with a history of delivering quality equipment and reliable support. Customer testimonials and case studies can provide insights into their performance and reliability.

- Extensive Product Catalogs: A supplier with diverse options allows you to compare features, prices, and compatibility, ensuring you find the best match for your needs.

- Training and Technical Resources: Vendors offering training sessions or detailed manuals empower your team to use and maintain the equipment effectively. Some suppliers even provide on-site training to ensure proper handling and operation.

- Comprehensive Support Services: Evaluate their ability to assist with troubleshooting, system integration, and ongoing maintenance. Accessible technical support minimizes downtime and addresses any issues swiftly.

- Post-Purchase Benefits: Features like extended warranties, upgrade options, and spare parts availability ensure that your investment remains valuable in the long term. These services often significantly reduce the total cost of ownership.

Choosing the right electric actuators based on industrial needs impacts efficiency, safety, and operational costs. Collaborating with experienced suppliers further simplifies the process, providing access to expert guidance, reliable support, and valuable resources. A thoughtful approach makes the right actuator a mainspring for operational excellence and sustained success in any industrial application.