The furniture industry is evolving faster than ever shaped by digital adoption, changing consumer expectations, and the pressure for speed, precision, and cost-efficiency. Whether you’re a furniture manufacturer, an interior designer, a design-led startup, or a growing retail brand, one thing is becoming increasingly clear: traditional 2D drawings alone can no longer support modern product development cycles.

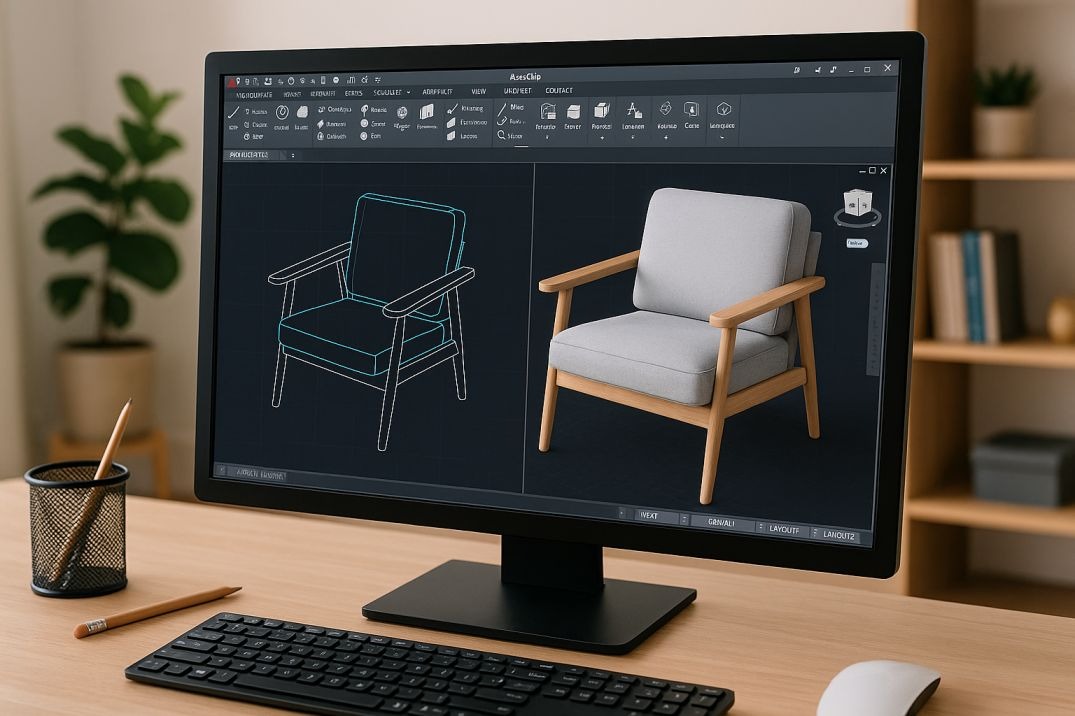

This is where AutoCAD 3D Furniture Design makes a transformational impact.

Today, brands around the world particularly in the UK’s rapidly digitalizing design and manufacturing sector are turning to 3D modelling to visualize complex components before a single piece of material is cut. It’s a shift driven by the need for accuracy, shorter prototyping cycles, and clearer communication between designers, engineers, and production teams.

In this article, we’ll explore why 3D modelling has become the backbone of modern furniture development and how AutoCAD-based 3D Furniture Design Drawing empowers teams to innovate without risks.

Why Are Brands Moving from 2D to AutoCAD 3D Furniture Design?

The shift from 2D to 3D has been driven by several forces: tighter deadlines, reduced budgets, and the push for more customized and modular furniture.

According to the UK Design Council, digital design adoption has accelerated across the industry as brands seek better tools for visualization, faster decision-making, and cleaner collaboration.

Meanwhile, global studies show rising complexity in furniture and interior product development. Modular systems, hidden joinery, knock-down (KD) fittings, multifunctional furniture, and ergonomic considerations require far more detailed representation than traditional drafting can offer.

With AutoCAD 3D Furniture Design, every joint, curve, hinge, and tolerance can be visualized precisely, reducing the chance of design conflicts or costly production errors.

How Does AutoCAD 3D Furniture Design Improve the Visualization of Complex Components?

1. Can 3D Furniture Models Show Hidden Parts and Internal Structures?

Absolutely; and this is one of the biggest advantages.

Traditional 2D drawings can only show so much. But with 3D Furniture CAD Design Services, designers can reveal:

- Internal frames

- Support structures

- Reinforcements

- Hidden hardware (hinges, brackets, connectors)

- Joinery and fasteners

- Material thickness and layering

Exploded views, section cuts, and detailed assembly diagrams make communication clearer for everyone involved from stakeholders to manufacturing teams.

This is particularly valuable for furniture categories such as:

- Modular office systems

- Upholstered furniture

- Storage units

- Retail display systems

- Custom or bespoke furniture

When internal components are clear, production errors decrease significantly.

2. How Does 3D Furniture Design Ensure Dimensional and Structural Accuracy?

With AutoCAD’s precision tools, brands can develop dimensionally accurate models that reflect real-world behavior.

3D design allows for:

- Accurate alignment and geometry

- Defined tolerances

- Correct fitment of machine-ready parts

- Realistic representation of material thickness

- Testing clearances for moving parts

- Evaluating load-bearing sections

Manufacturers particularly benefit from this accuracy, as CNC routing, milling, and laser cutting depend on precise digital files.

Recent studies highlight how design-related inaccuracies continue to drive costly rework in manufacturing and construction. For example, a report by the National Association of Manufacturers notes that poor design documentation remains a major cause of production waste in fabrication industries.

By improving accuracy early in the process, brands significantly reduce rework and scrap.

3. How Do 3D Furniture Models Speed Up Approvals with Clients and Stakeholders?

Modern buyers, especially B2B clients, expect visual clarity. They need to see what the furniture will look like across multiple configurations, materials, and spaces.

With AutoCAD 3D Furniture Design Services, it becomes easy to generate:

- Render-ready models

- Clean 3D views (isometric, perspective, orthographic)

- Multiple material variations

- Assembly instructions

- Photorealistic outputs (when paired with visualization tools)

These assets make presentations smoother and more convincing.

This is particularly beneficial for:

- Architects pitching interior designs

- Interior designers submitting furniture proposals

- Retail brands testing new product lines

- Manufacturers seeking client signoff before tooling

- Startups developing prototype concepts

3D visualization reduces subjective interpretation, helping teams make decisions faster and more confidently.

4. How Does 3D Furniture CAD Design Reduce Manufacturing Errors?

Errors often come from miscommunication, a known challenge in the construction and manufacturing sectors.

With 3D Furniture Design Drawing, every component is represented exactly as it will be manufactured. This eliminates ambiguity caused by:

- Overlapping 2D lines

- Missing dimensions

- Vague annotations

- Misinterpreted scale

- Unclear joinery information

Manufacturing teams get clearer instructions, which leads to fewer:

- Reworks

- Delays

- Material wastage

- Adjustments during assembly

More importantly, 3D models can be imported directly into manufacturing software improving automation and reducing manual dependency.

5. How Does AutoCAD 3D Furniture Design Support Modular and Bespoke Furniture?

The UK’s furniture and interior industry has seen rising demand for:

- Sustainable furniture

- Bespoke and artisanal products

- Modular workspace solutions

- Space-saving residential furniture

- Multi-functional products

Complexity in these categories often requires customizable models that can be adjusted quickly.

AutoCAD 3D modelling enables:

- Easy modification of sizes and proportions

- Quick changes to joinery or internal components

- Faster generation of variants and configurations

- Rapid prototyping for new concepts

- Integration into BIM and larger architectural environments

This supports agile product development essential for both SMEs and large global furniture brands.

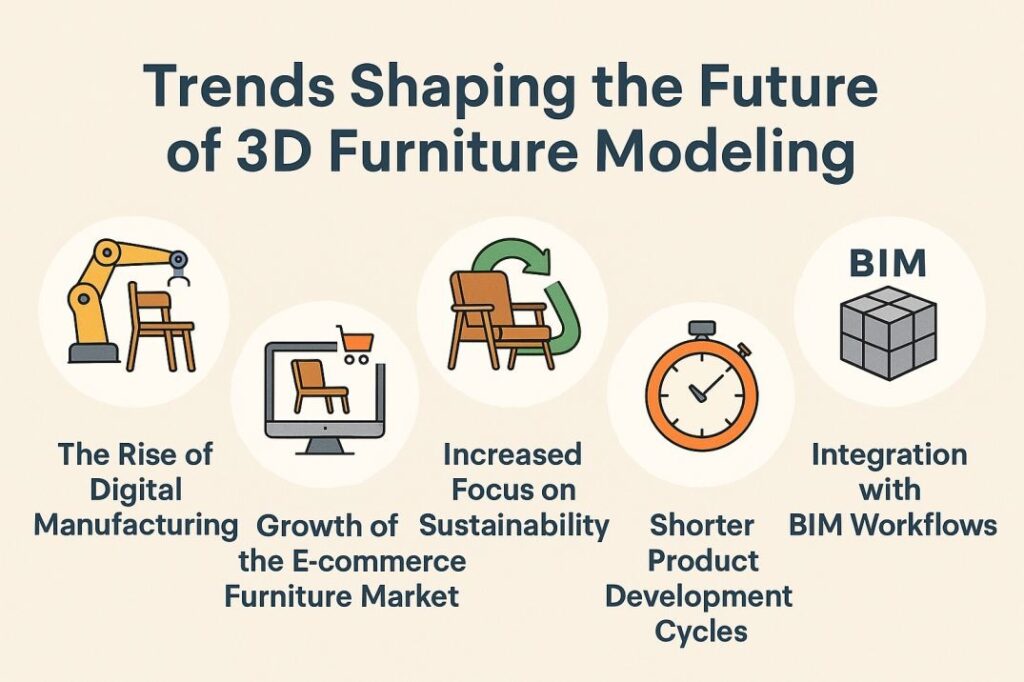

What Industry Trends Are Driving the Demand for 3D Furniture Modeling?

1. The Rise of Digital Manufacturing

CNC machining, 3D printing, and automated fabrication rely entirely on clean digital models.

2. Growth of the E-commerce Furniture Market

Online retailers need 3D models, AR assets, and visualization files for product listings.

3. Increased Focus on Sustainability

Digital prototyping reduces reliance on physical samples helping brands cut waste.

4. Shorter Product Development Cycles

Businesses need faster approval cycles to stay competitive. 3D models allow quicker decision-making.

5. Integration with BIM Workflows

Furniture must fit into architectural models especially in commercial, residential, and hospitality projects. Accurate 3D CAD files make this seamless.

How to Choose the Right 3D Furniture CAD Design Services Provider

When selecting a 3D Furniture Design Services partner, consider the following:

1. Experience with AutoCAD and Multi-Software Expertise

Look for expertise not just in AutoCAD but also SolidWorks, Fusion 360, SketchUp, 3ds Max, and Revit.

2. Quality of Past Furniture Models

Ask for samples showcasing:

- Hardware detailing

- Clean topology

- Accurate dimensions

- Realistic material representation

3. Industry-Specific Knowledge

Choose a provider familiar with:

- Joinery

- Fabrication processes

- Manufacturing standards

- Ergonomics

4. End-to-End Support

The partner should offer:

- Concept modelling

- 3D Furniture Design Drawing

- Rendering

- Shop drawings

- BOM creation

5. Communication & Speed

Effective collaboration is key especially for fast-moving projects.

Also Read: Top Features to Look for in the Best Omegle Alternative

Conclusion

As furniture brands in the UK and worldwide continue to adopt digital workflows, AutoCAD 3D Furniture Design is emerging as an essential tool for visualizing complex components, improving accuracy, reducing errors, and speeding up approvals.

Whether you’re designing a modular furniture range, launching a new product line, or managing large-scale interior projects, 3D modelling helps you innovate with confidence.

For businesses looking to streamline their design-to-production cycle, partnering with an experienced UK-based 3D Furniture Design Company can make all the difference offering precision, consistency, and long-term design scalability.