You’ve probably heard the buzz: handheld laser welders are quietly causing a shake-up in how we build things these days. They’re not just another tool—they’re more like the secret weapon you didn’t know you needed. Small, precise, adaptable—it’s almost magical how much they can enhance workflows.

Why the fuss? It’s all about smart energy use. These tools deliver pinpoint heat exactly where it’s needed, cutting down on warping, defects, and cleanup. As manufacturers chase efficiency and lean operations, this tech is creeping into more shops—and fast.

Introduction

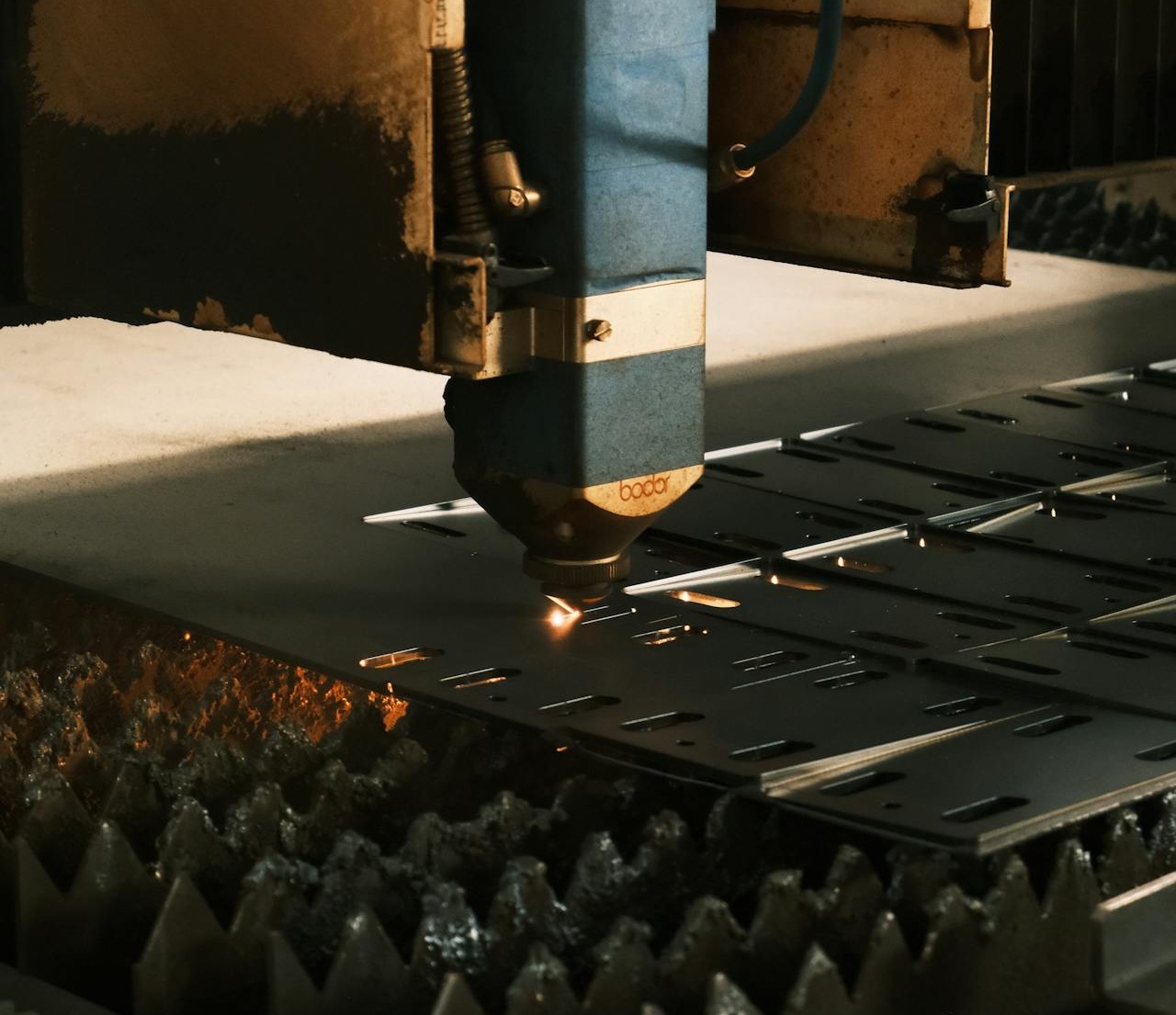

Think of handheld laser welder as the nimble cousin of their industrial counterparts. They’re compact but pack a serious punch. Whether you’re welding on location or trying to finesse tight spots, these welders bring surprising versatility.

It’s not just about heat control, though that’s a big part of it—keeping things cool keeps things tight. And in a world where precision and cost are equally king, handheld laser welders are gaining serious momentum.

Precision & Minimal Distortion

Here’s the deal: with a handheld laser welder, you’re basically wielding a scalpel instead of a sledgehammer. The beam goes exactly where you tell it, creating clean seams and leaving little to no cleanup behind.

And the heat—it’s laser focused, not broadcasted. That means your parts stay in shape, no surprise warps messing things up. Throw fewer rejects into the mix, and suddenly you’ve got quality, confidence—and even a smoother workflow.

Speed & Productivity Gains

These welders move fast. Once you dial in the settings, you’ll find yourself zipping through welds in no time. No fuss, no mess, just rapid-fire precision.

Because you’re not spending time reworking edges or fixing warps, the whole process flows better. It’s the kind of speed that makes deadlines less scary and customers happier. Plus, setup is quick—so projects keep moving, not stalling.

Portability & Versatility

One of my favorite things? You can carry these welders wherever you need them. No need to drag heavy gear around—take it with you. And when space is tight, they’re just easier to handle.

They adapt well, too. Steel? Sure. Aluminum? Absolutely. Change materials, tweak settings, and they flex to your needs. Tight angles or odd shapes? This tool has your back.

Cleaner, Safer Operation

Imagine less smoke, fewer fumes, and way less cleanup elbow grease. That’s what happens with a handheld laser welder. The beam’s precision cuts back on mess, and your shop stays tidier and healthier.

And because there’s less stray heat, you’re not risking damage or burns. Some models even offer features like built-in shields or enhanced visibility—making it safer all around.

Lower Total Cost of Ownership

At first glance, the price tag might raise eyebrows—but dig deeper and you’ll notice the long game benefit. These welders are built tough but simple—fewer parts to go wrong, longer service life, and lower maintenance headaches.

Plus, they’re energy-smart. Less power, less waste, fewer materials needed—everything stacks up to savings. And because operators can run them faster, your labor costs shrink, too.

Industry Applications & Impact

You see handheld laser welders popping up in automotive shops, fab plants—I even saw one being used in airplane assembly the other day. They’re perfect for precision jobs on steel, aluminum, even electronics.

Need to work in cramped spaces or bring the tool right to the workpiece? This is your answer. They’re adapting old-school jobs to today’s need for speed, cleanliness, and reliability.

Market Trends & Technological Innovation

The market isn’t slowing down: more manufacturers are adding these welders to their lineup. And tech keeps pushing further—smart sensors, real-time feedback, data-tracking. It’s welding with a brain now.

These days, they’re lighter, smarter, more portable. Plus, folks care more about sustainability—less waste, fewer emissions—so these welders check those boxes, too.

Challenges to Adoption

Let’s be real: there’s a learning curve, and the upfront cost might sting. Plus, there are safety rules to follow—lasers mean eye protection and training, no shortcuts.

And for heavy industrial work, these might not replace giant rigs. But for on-the-spot, precision tasks, Denaliweld systems are knocking it out of the park.

Also Read: The Role of Multimode Laser Diodes in High-Power Applications

Conclusion

Handheld laser welders aren’t just another trend—they’re changing how we think about welding. They’re precise, nimble, and efficient. The early investment pays off with faster work, less waste, and cleaner results.

Sure, they’re not perfect for every situation—but for lightweight, intelligent manufacturing? They’re a game changer. If you’re trying to stay competitive, efficient, and ahead of the curve, these tools deserve a spot in your toolkit.